What Is Associated Gas?

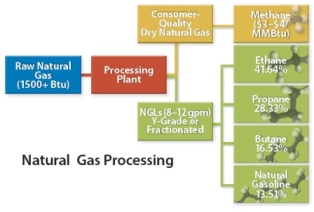

Crude oil extracted from geologic reservoirs contains a mixture of hydrocarbon molecules. When pumped to the surface, liquid crude oil is separated from hydrocarbon gases at the wellsite. Oil is stored in tanks until it can be transported from the wellsite by pipeline or truck. The gaseous fraction, or "associated gas," cannot be stored in tanks as easily as liquid hydrocarbons and is typically "gathered" via small, low-pressure pipelines. This associated gas is transported to large gas-processing facilities where the natural gas (methane and some ethane) is separated from the various other gases. The other gases include propane, butane, pentane, and small amounts of hexane and heptane and are called natural gas liquids (NGLs). These can be marketed for further processing in the petrochemical industry.

Why Does Flaring Occur?

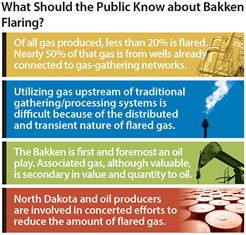

Associated gas is flared when oil is produced, but gas-gathering infrastructure (including pipelines, compressor stations, and gas-processing facilities) is insufficient to accommodate the amount of associated gas. This can happen when gas-gathering pipelines have not been connected to a wellsite, when gas-gathering infrastructure has insufficient capacity, or when a process upset temporarily interrupts operation. Under these circumstances, gas separated from produced oil is directed to a flare to burn unused gas to prevent release to the atmosphere.

Utilizing gas upstream of traditional gathering/processing systems is difficult because of the distributed and transient nature of flared gas. The location of flares changes as new wells are drilled and gathering pipelines installed. Additionally, gas production rates can drop as much as 65% over the first year of production. This dramatic change makes selecting appropriately scaled equipment difficult.

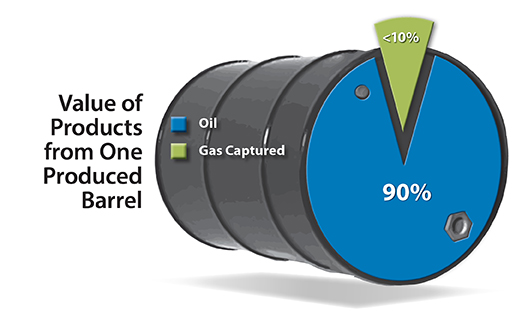

The Bakken is first and foremost an oil play. Associated gas, although valuable, is secondary in value and quantity to oil. For each barrel of oil produced in North Dakota, approximately 90% of the value comes from oil, and less than 10% from associated gas.

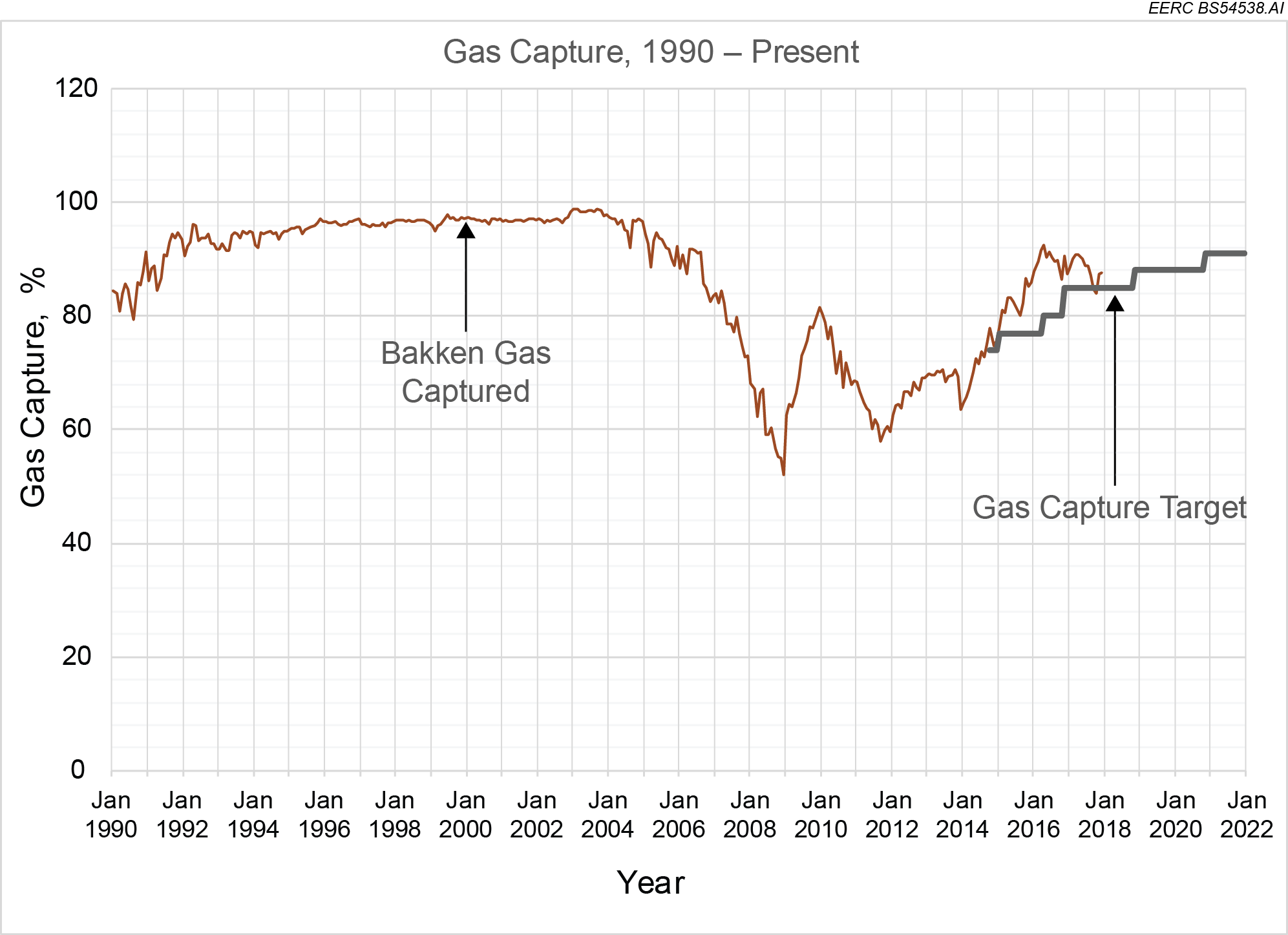

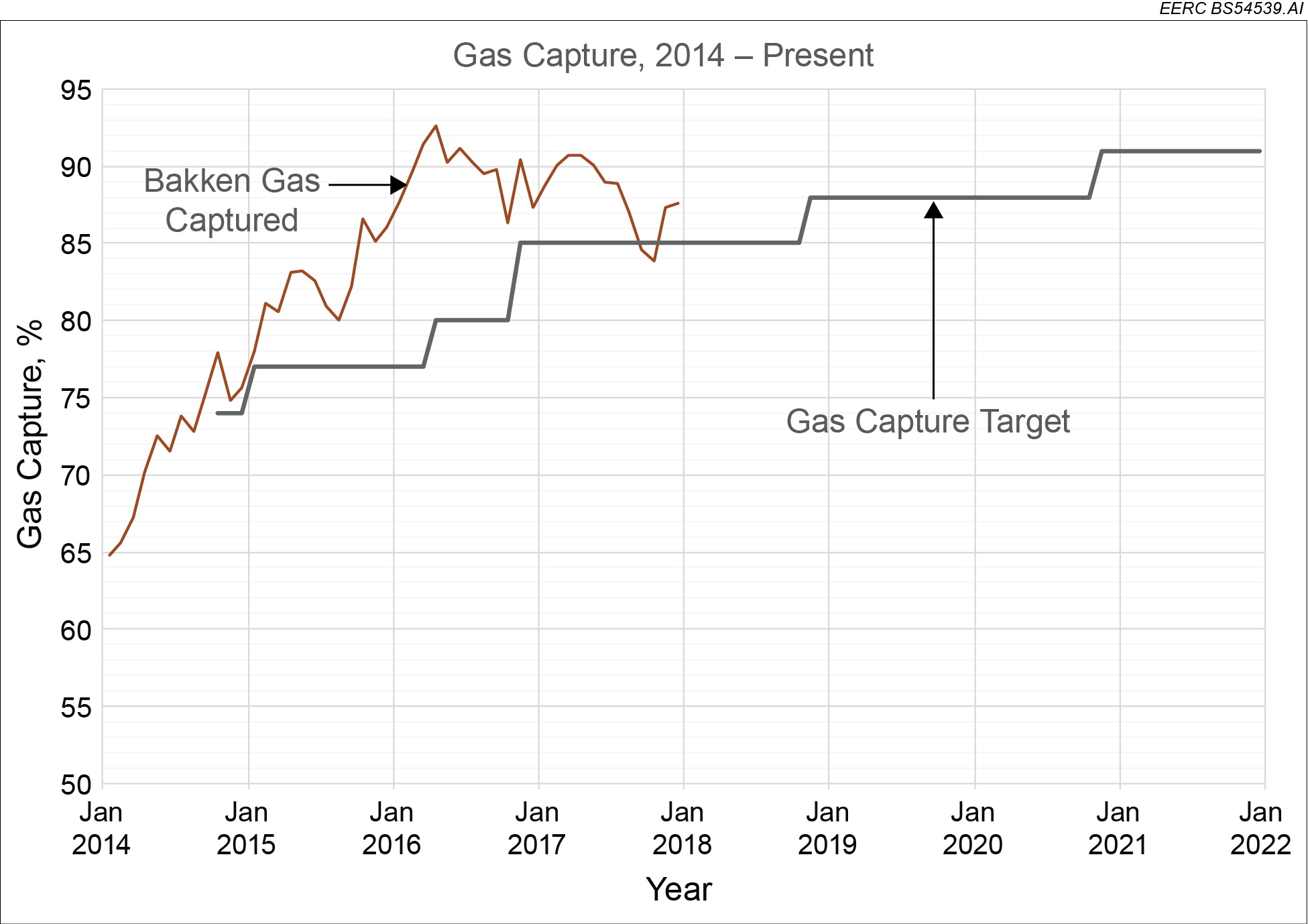

There is a desire by all parties to see all associated gas captured and marketed: maximizing profits, ensuring efficient use, and minimizing environmental impacts. As the Bakken play matures, it is expected that nearly all produced gas will be captured.

How Is Flaring Regulated?

The North Dakota Industrial Commission (NDIC) Oil and Gas Division implements and enforces oil- and gas-related regulations. Typically, state law allows oil production to occur at varying rates during the first several months of operations to determine production rates. Gas can be flared while data are collected to assess the viability and determine gas-gathering capacity requirements. Thereafter, production may be restricted if statewide gas capture goals are not met. North Dakota Industrial Commission Order No. 24665 defines a graduated set of flare reduction targets aimed at reducing associated gas flaring through 2020. Besides connecting produced gas to gas gathering pipelines, acceptable gas uses include electrical generation, well site NGL recovery, compression and/or liquefaction of natural gas for use as a transportation fuel, or conversion to a chemical or fuel. (https://www.dmr.nd.gov/oilgas/GuidancePolicyNorthDakotaIndustrialCommissionorder24665.pdf.)

What Is Being Done to Reduce Flaring in North Dakota?

Rapid Infrastructure Buildout by Industry. As activities in the Bakken continue transitioning from single well pads to in-fill drilling (in which additional wells are drilled at already-producing wellsites), gathering infrastructure should be more readily available and reduce the necessity for flaring.

New Technology Investigations. The Energy & Environmental Research Center (EERC) conducted an assessment of alternative gas uses upstream of traditional gas-processing plants. The study investigated using associated gas for power production, transportation fuel, and chemical production, as well as analyzed small-scale gas processing to recover NGLs. Although intriguing, the economic viability of these alternatives was complicated by the distributed and transient nature of flared gas, requiring innovative approaches to effective implementation.

Another project completed by the EERC demonstrated the use of wellhead gas as a fuel for the diesel generators powering drilling rigs. Results from the project indicated that 1.8 billion cubic feet of gas could be used annually to power 200 drilling rigs in North Dakota, saving over $72 million in fuel cost.

Currently, the EERC and our partners are working collaboratively to further improve the efficiency of wellsite operations, including gas use and flaring.