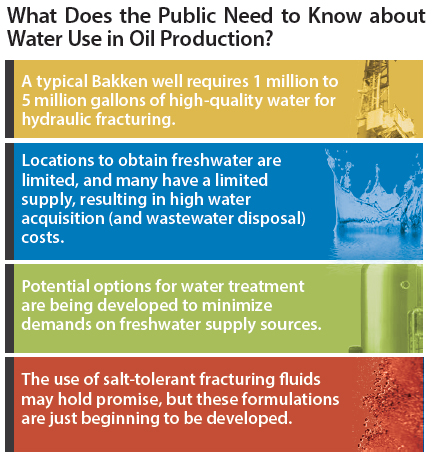

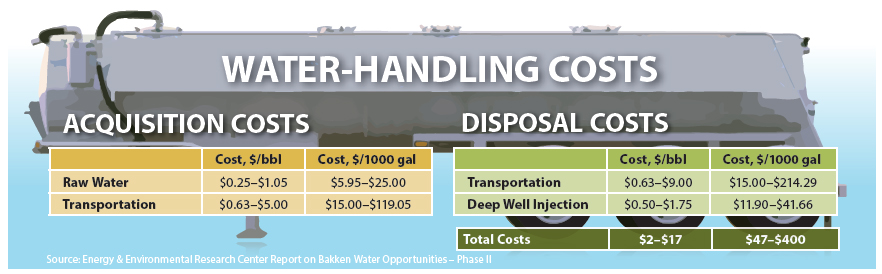

Water is a critical ingredient for oil and gas development within the unconventional oil reservoirs of western North Dakota. Because of the current high costs for acquisition, disposal, and transportation of existing potable water resources in the region, treatment and/or use of nontraditional water supplies may be an economically viable alternative. The Energy & Environmental Research Center (EERC) is currently engaged in a project to investigate and accelerate development of new options to reduce freshwater consumption in Bakken production operations and decrease water costs to production operations.

How Is Water Used in Oil and Gas Production?

Development of one of the largest unconventional oil and gas plays in North America is occurring in North Dakota and Montana, with oil from the Bakken and Three Forks Formations being produced at over 800,000 barrels a day. It is estimated that there are hundreds of billions of barrels of oil in these formations. Robust development is expected to continue for at least another decade. While development of these resources clearly enhances the nation’s energy security, a number of challenges are associated with that development, including the need for substantial volumes of water for hydraulic fracturing operations.

How Much Water Are We Talking?

Hydraulic fracturing is a process that injects a blend of mostly water with minor amounts of various additives at high pressure into these deep formations to create fractures and flow paths necessary for oil and gas extraction from rocks with very low permeability. A Bakken well requires 1 million to 5 million gallons of water for hydraulic fracturing. The North Dakota Department of Mineral Resources estimates that 20 million to 30 million gallons of water a day, or 7.3 billion to 11 billion gallons of water a year, will be needed over the next few decades.

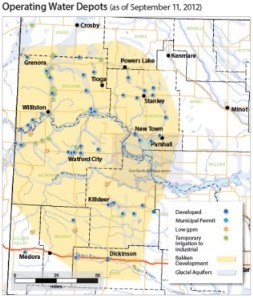

Where Do Producers Get the Water?

While the volumes of water used for hydraulic fracturing are not especially high when compared to those needed for municipal and agricultural use within western North Dakota, in some areas there is a high degree of competition among various users for limited freshwater supplies. As shown below, there are a limited number of locations from which to obtain freshwater. Many such water depots and municipalities have a limited supply. The Missouri River system has an abundant supply of water, but federal concerns over suitable access points have delayed and/or limited access. Most other surface water bodies in the region are small and do not provide a reliable supply of water because of seasonal flow variations.

For water haulers, the limited number of water supply locations translates to long transportation distances and excessive amounts of time spent waiting in lines at water depots, resulting in high water acquisition (and wastewater disposal) costs for Bakken oil producers. Given the current demand for water resources and the high costs of transportation, the oil and gas industry is motivated to explore options for water reuse and/or recycling.

What Options Do We Have?

As treatment technologies and fracturing fluid systems advance, there may be potential options for treatment, reuse, and/or recycling of nontraditional water supply sources for use in Bakken development, such as:

- Treatment and reuse of the water used for hydraulic fracturing after it returns to the surface (referred to as flowback).

- Treatment and use of wastewater from other nontraditional sources, such as saline groundwater and municipal wastewater.

- Use of hydraulic fracturing fluid systems that work with saline water rather than high-quality water.

The above approaches are not without challenges. For example, Bakken flowback tends to be very salty, and only a portion of it returns to the surface (typically about 25% or less), making treatment difficult and limiting the amount available for reuse. Treatment of other nontraditional water sources may be easier, but transportation costs may be too high. The use of salt-tolerant fracturing fluids may hold promise, but these formulations are just beginning to be developed. While industry recognizes the benefits of water recycling and reuse for Bakken development, these challenges have prevented widespread implementation to date.

How Will Development of New Water Options Benefit North Dakota?

Industry development of new technologies to recycle or otherwise utilize flowback, produced water, or saline groundwater would provide multiple benefits to the state and industry and improve the quality of life for residents impacted by truck traffic and associated dust and road maintenance issues. Some of the key benefits include the following:

- Decreased demand on freshwater resources

- Decreased wastewater disposal costs and associated costs for industry

- Fewer issues associated with the heavy volume of truck traffic in the region, such as road maintenance, dust control, and air emissions

- Increased versatility in water supply options, resulting in decreased production costs

- Decreased environmental footprint for Bakken development

The above approaches are not without challenges. For example, Bakken flowback tends to be very salty, and only a portion of it returns to the surface (typically about 25% or less), making treatment difficult and limiting the amount available for reuse. Treatment of other nontraditional water sources may be easier, but transportation costs may be too high. The use of salt-tolerant fracturing fluids may hold promise, but these formulations are just beginning to be developed. While industry recognizes the benefits of water recycling and reuse for Bakken development, these challenges have prevented widespread implementation to date.