Completion Technologies

There is significant variability in the well completions across the Williston Basin. Generally, the characteristics can be summarized as follows. The majority of wells are completed on 640- or 1280-acre spacing, resulting in 5000- and 10,000-ft horizontal wellbores, respectively. Operators that have already developed fields are now conducting in-fill programs, drilling as many as three wells within a given spacing unit in the Bakken and Three Forks Formations. Most wells are positioned in a north-south or northwest-southeast orientation to either take advantage of induced fracture propagation in the direction of maximum horizontal stress or to simply protect lease lines allowing for in-fill spacing or potential patterning for secondary/tertiary recovery projects. In all cases, wells are lined with casing from the surface to the base of the curve in accordance with state and federal regulations and to ensure the formation remains isolated from fluids in overlying formations. Operators have appeared to settle on single lateral completions in North Dakota. However, many variations of multilateral completions and orientations have been attempted. The lateral completions vary and are described below, including cemented liners, openhole completions, and noncemented liners with and without positive annular isolation.

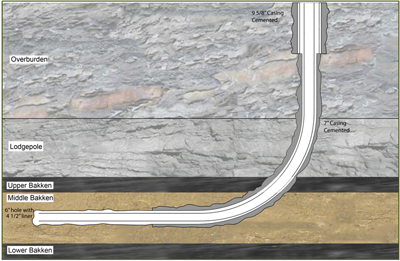

Cemented liner completions involve cementing the liner throughout the horizontal wellbore, allowing control of wellbore stability, direct control of fracture initiation, and greater well serviceability. Drawbacks include the potential for formation damage during completion and the potential isolation of natural fractures that would otherwise contribute to conductivity in the openhole. Commonly, the “plug-and-perf” stimulation technique is employed in wells with cemented liners. Plug-and-perf includes pumping down a bridge plug on wireline with perforating guns to a given horizontal location near the toe of the well. The plug is set, and the zone is perforated. The tools are then removed from the well, and the fracture stimulation treatment is pumped in. The set plug or ball-activated plug then diverts fracture fluids through the perforations into the formation. The stage is completed, the next plug and perforations are initiated, and the process is repeated moving back to the heel of the well. Cemented liners can also be used in single-stage fracturing operations, although they are less common in current Bakken completion practices.

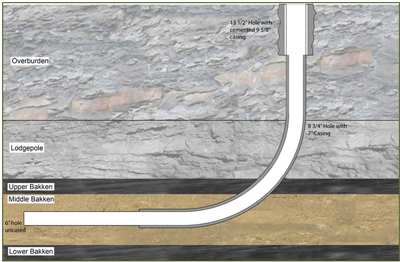

Openhole completion is the most basic technique utilized in the Bakken. Early in the Bakken play, openhole completions were utilized for limited-entry fracture stimulation in which the entire lateral was treated in a single fracture treatment. The method is relatively quick and inexpensive and has good potential for improved recovery from refracturing techniques. Single-stage fracturing in the openhole provides little control over fracture initiation and propagation. Other methods of openhole completions include the insertion of liners and ball-actuated sliding sleeve systems for multistage fracturing.

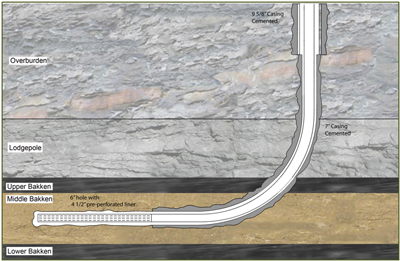

Uncemented, preperforated liners can be inserted in the wellbore absent of annular isolation or with positive annular isolation. The objective of the preperforated liner without annular isolation is to provide a means to control fracture initiation and propagation by diverting fluids using perforation ball sealers, large-size proppant slugs, high-concentration proppant slugs, or fibers. The liner may be preperforated, at custom or regular intervals prior to emplacement, or perforated below the surface with an explosive device known as a perforation gun. The space between the liner and the wellbore (the annulus) is open, allowing formation fluids to freely migrate both inside and outside of the liner. The options for pumping the stimulation treatment inside preperforated liner vary and are frequently adjusted relative to the pressures and pumping history recorded during the job. Positive annular isolation of the liner provides for multistage fracture treatment methods described below.

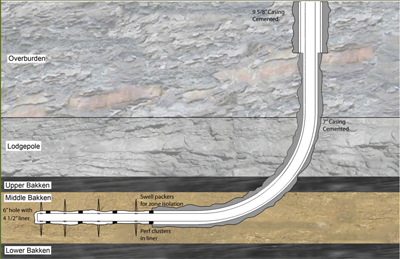

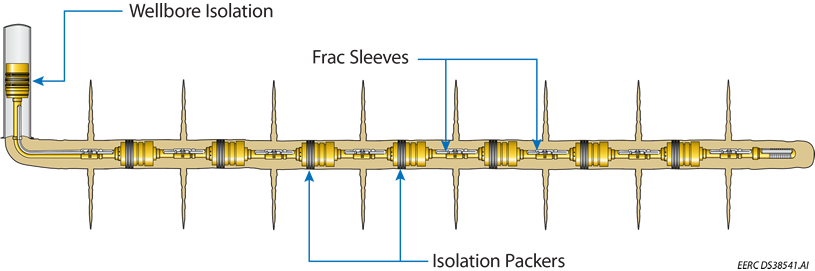

Positive annular isolation of an uncemented liner is generally achieved with swell packers. The liner includes attached packers set at various intervals and designed to swell when introduced into the downhole environment to form a tight seal in the annular space of the wellbore. Both oil-based and water-based packers are available and matched with other downhole conditions such as temperature. Time is required to allow the packers to swell, usually a matter of a few days. The system typically remains in the well. However, there may be instances where swell inhibitors are applied to accommodate the development schedule. Liners may be preperforated and can accommodate either multistage frac-sleeve systems or plug-and-perf stimulation technologies. Uncemented liners with swell packers are a popular completion option in North Dakota, particularly for wells with large numbers of fracture stages.

Mechanical isolators or ball-actuated sliding sleeves have been utilized extensively in Bakken completions. The systems can be run inside a liner or in the openhole. The system comprises ported sleeves installed between isolation packers on a single liner string. Packers isolate the horizontal wellbore into stages. A ball dropped into the fluid and pumped down the string will seat in the mechanical sleeve. This action will open the sleeve exposing the ports and diverting the fluid to the formation, which creates a hydraulic fracture within the isolated zone. This system is operated by pumping progressively larger-sized balls and operating sleeves from the toe of the well to the heel. The well is cleaned out by flow back to the surface, which returns fluid and solid particles. The balls and ball seats can be drilled out with coiled tubing. The technology allows for a quick and efficient fracture stimulation operation by minimizing fluid use, limiting trips downhole, and streamlining the pumping operation. Challenges include the potential for limited insertion of the tool string and failure of balls and seats in the opening of the sliding sleeves.

Completions in the Bakken Formation

Since horizontal drilling became standard practice over the past two decades, all of these completion methods have been utilized in the Bakken. However, the uncemented, preperforated liner isolated with swell packers has become the most commonly employed method of completion in most Bakken wells because of its high degree of fracture control and long-term success rate.