Stimulation Technologies

Stimulation relative to the Bakken Formation refers primarily to the hydraulic fracturing process of the horizontal wellbore. Hydraulic fracturing is performed to create greater conductivity of fluids within the formation and improved communication with the reservoir and the wellbore. The components of hydraulic fracturing include the hydraulic fluids and the proppants used to keep fractures within the rock open. Fracturing fluids are designed to inhibit corrosion, minimize bacteria growth, carry proppants into the induced fractures, and minimize reactivity with the formation. Generally, the fluids comprise water and dilute chemicals to provide improved properties. Proppants include sand and ceramics of specific sizes, strengths, and treatments that increase the likelihood for the proppant to remain in the formation versus flowing back to the surface with the fluids.

Hydraulic Fracture Stimulation Treatments

The size and type of hydraulic fracture treatments utilized in the Bakken Formation of North Dakota have varied over time. An example of a hydraulic fracture treatment for one operator in 2008 included the use of 950,000 gallons of fluid to place 1.9 million lb of proppant in a 5000-foot horizontal well. An example of a well in 2010 with a horizontal length of 10,000 feet used approximately 3.5 million gallons of fluid to place 4.5 million lb of proppant. Hydraulic fracture treatments can be pumped as a single stage where the entire horizontal wellbore is fractured at one time or in multiple stages. Multiple-stage completion methods such as sliding-sleeve systems are typically employed first at the toe of the well treating a 250- to 500-foot zone isolated by packers and working toward the heel of the well. Modern technology allows the sequential multistage treatments to be conducted without the interruption of running tools into the well and decreasing treatment times to as little as 24 to 48 hours. The number of fracture stimulation stages in a Bakken or Three Forks well has increased to 40 stages in 2011 with the size of the job. Treatment costs vary, however. Stimulation treatments typically cost more than $2 million.

Fracturing Fluids

The selection of fracturing fluid is largely based on personal experience, geographic considerations, and advice from service providers. Generally, treatments in the Bakken have used water-based fluids. Fracturing fluids are required to be viscous enough to create a fracture of adequate width, maximize fluid travel distance to extend fracture length, transport large amounts of proppant into the fracture, and utilize gelling agents that break down to allow flowback of fluid and reduce flowback of proppant.

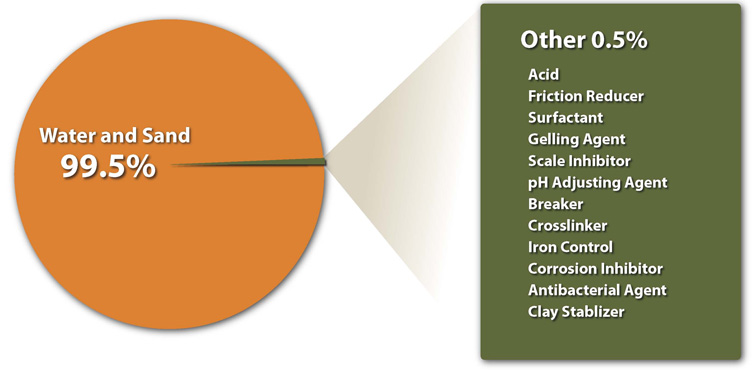

Additives to the fracturing fluids are used in a numbers of ways. The figure below lists potential additives and shows the general concentration of additives relative to the total volume of fluid. Fluid additives function to clean up the formation, prevent leakoff, and reduce surface tension. The additives include biocides, fluid-loss agents, enzyme breakers, acid breakers, oxidizing breakers, friction reducers, and surfactants. Primary categories for fracturing fluids include the following:

- Gelled fluids – linear or cross-linked gels

- Foamed gels

- Water and potassium chloride

- Combinations of the above

Descriptions of fracturing fluids and corresponding additives are as follows. Linear gels include agents known as guar or cellulose derivatives that are biodegradable. The substances are polymeric, which thicken the water for better proppant transport. Guar gum is nontoxic and is a food-grade product commonly used to increase the viscosity of foods such as ice cream. Cross-linked gels are an improvement to linear gels providing greater proppant transport properties. Cross-linking reduces the need for fluid thickener and extends the viscous life of the fluid indefinitely. Metal ions such as chromium, aluminum, and titanium are used to achieve the cross-linking. Cross-linked fluids require breaking agents to reduce the viscosity for flowback. Breakers are additives of acids, oxidizers, or enzymes. Foamed gels use bubbles of nitrogen or carbon dioxide to transport proppant into fractures. The inert gases can reduce the amount of fluid required for fracturing by up to 75%.14 Potassium chloride is sometimes used as a thickening agent for water-based fracturing fluids. Polymers in hydraulic fracturing fluids can provide a medium for bacterial growth. The bacteria can secrete enzymes that break down gels and reduce viscosity, which translates to poor proppant placement. Biocides are added to inhibit microbial action. Leakoff is the action of fracturing fluids emanating from the fracture into the rock matrix in which a fracture does not exist. Leakoff is controlled by adding bridging materials such as 100-mesh sand, soluble resin, or other plastering materials. Pumping of stimulation fluids can occur at maximum rates in which friction from high-viscosity fluids requires significant horsepower. Friction reducer additives are used to minimize energy requirements and primarily consist of latex polymers.

Proppants

A proppant is a hydraulic fracturing fluid additive that is used to hold the hydraulic fracture open and allow the flow of reservoir fluids. Proppants typically comprise sand or manufactured ceramics such as bauxite. Proppants can be resin-coated to improve packing, which helps the proppant stay in place and not flow back to the wellbore. Resin coatings also help provide better distribution of stress over the proppant pack. Proppants are specified in grain diameter sizes of less than 1/16 of an inch. Some common mesh sizes are 16/20, 20/40, 30/50, 40/70, and 100. Treatments may use one size or a multitude of sizes during pumping. The smaller sizes are intended to reach closer to the fracture tip. A propped hydraulic fracture has a significantly greater fluid (hydraulic) conductivity than the surrounding lower permeability rock matrix. Challenges to stimulation treatments involve proper placement of proppant, prevention of crushing or embedment, plugging at restrictions, and potential flowback of proppant to the wellbore.